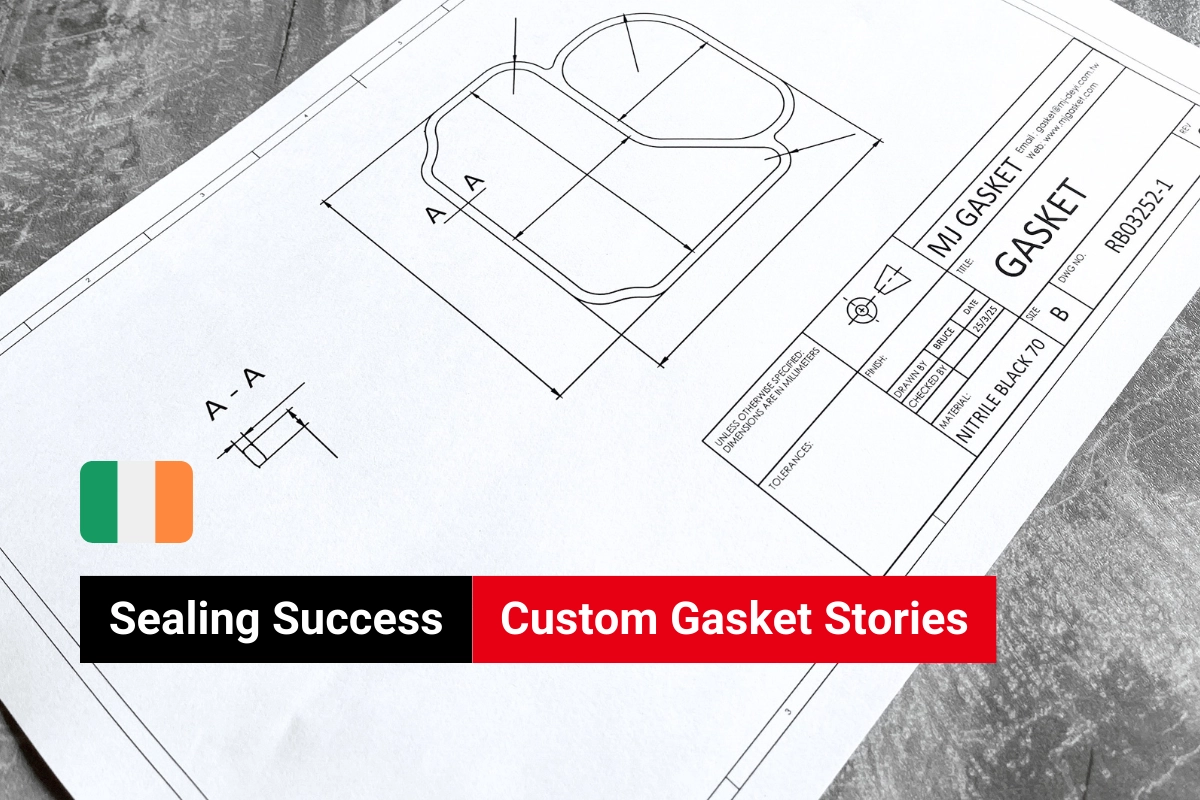

Case ID: MJ-CS-18-003

A client from Ireland, specializing in industrial equipment manufacturing, reached out to us with a detailed technical drawing, outlining their specific needs for a custom Nitrile Rubber Gasket to suit their equipment. Along with the drawing, they also provided the required quantities for the quote, ensuring we could tailor our solution to meet their precise needs.

Nitrile Rubber Gasket Overview

Nitrile rubber (NBR) is a highly durable material widely used in gasket applications due to its exceptional resistance to oils, fuels, and chemicals. Some of the key features of Nitrile Rubber Gaskets include:

- Oil and Fuel Resistance: Excellent resistance to oils, fuels, making it ideal for sealing applications in industrial environments.

- Durability: Strong mechanical properties, including flexibility and resistance to wear, ensuring long-lasting performance.

- Temperature Resistance: Withstands a wide range of temperatures, making it suitable for various industrial applications.

- High Sealing Efficiency: Provides reliable sealing performance even under high pressure and demanding conditions.

- Chemical Resistance: Offers protection against many chemicals, enhancing its versatility in different industrial sectors.

- Common Applications: Used in automotive, heavy machinery, and industrial equipment, providing effective sealing against oils and chemicals.

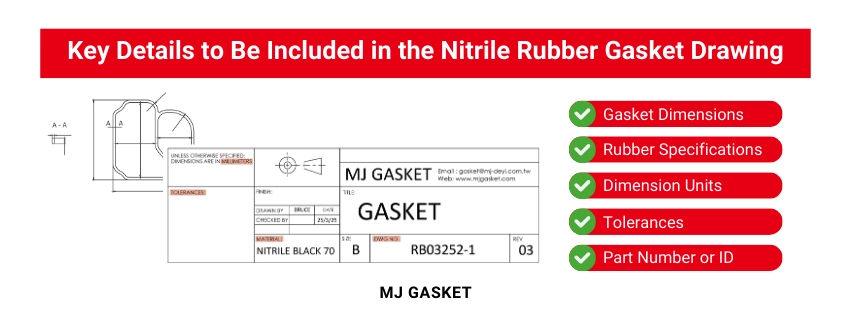

Key Details to Be Included in the Nitrile Rubber Gasket Drawing

To ensure the custom Nitrile Rubber Gasket meets the client’s requirements, several essential details need to be included in the technical drawing:

A. Gasket Dimensions:

Accurate measurements are crucial for ensuring a perfect fit within the specified assembly. The drawing should include:

- Inner and Outer Dimensions: Precise measurements of the inner and outer Dimensions to ensure a proper fit.

- Hole Diameters: Any holes for bolts or other components should be clearly specified for proper alignment and sealing.

- Thickness: The thickness of the gasket is essential for the correct compression and sealing performance.

- Special Notches or Cutouts: If the gasket requires any unique notches or cutouts, these must be detailed to avoid manufacturing errors.

B. Nitrile Rubber Gasket Material Specifications

The type of rubber required should be clearly defined, including:

- Hardness: The durometer (hardness) of the rubber, which influences the gasket’s sealing and performance.

- Temperature Resistance: The rubber’s ability to withstand heat or cold, ensuring it performs under the specific conditions of the application.

- Other Performance Characteristics: Any additional features, such as chemical resistance, flexibility, or durability, based on the client’s specific needs.

C. Tolerances

Clearly specifying acceptable tolerances ensures the gasket meets the exact requirements. This includes:

- Dimensional Tolerances: The allowable variations in size to maintain a precise fit within the assembly.

- Material Thickness: Tolerances for the material thickness to ensure consistent performance and sealing capabilities.

D. Dimension Units

All measurements should be provided with consistent dimension units, such as millimeters (mm) or inches (in), based on the client’s standard preference.

E. Part Number or ID

Each gasket should be clearly identified with a unique part number or ID for easy reference and ordering, facilitating efficient tracking and reordering.

**Please rest assured that all your technical drawings will be kept strictly confidential. We prioritize your privacy and ensure secure handling throughout the entire process.

First Article Sample for the Nitrile Rubber Gasket

Once we receive all the necessary information for the custom Nitrile Rubber Gasket, a first article sample is produced. This sample undergoes rigorous testing to ensure it meets the specified requirements before full production begins. It allows us to verify the dimensions, material properties, and overall quality to ensure it aligns with the client’s needs.

Sample Inspection by MJ QC Team

Before sending the sample to the client, our Quality Control (QC) team conducts a thorough inspection. Using the Keyence dimension measuring machine, we accurately check all dimensions to ensure precision. Additionally, our team verifies the material hardness. By maintaining high standards at this stage, we ensure the Nitrile Rubber Gasket meets the required quality before client evaluation.

Client QC Team Sample Review

After the samples are inspected by the MJ QC team, we send them to the client for quality inspection. The client will verify the gasket’s fit, functionality, and overall performance. This review process ensures that the Nitrile Rubber Gasket meets the client’s specific requirements.

Partner with MJ Gasket for Your Custom Nitrile Rubber Gasket Needs!

Looking for a reliable Nitrile Rubber Gasket solution? At MJ Gasket, we specialize in delivering high-quality, custom-made gaskets to meet your exact specifications. With our expertise and precision inspection process, we ensure every gasket performs to the highest standards. Contact us today to discuss your custom gasket requirements and let’s create the perfect solution for your application!

To speed up the evaluation process and minimize communication time, please send the detailed technical drawing of your gaskets to gasket@mj-deyi.com.tw.