Case ID: MJ-CS-19-001

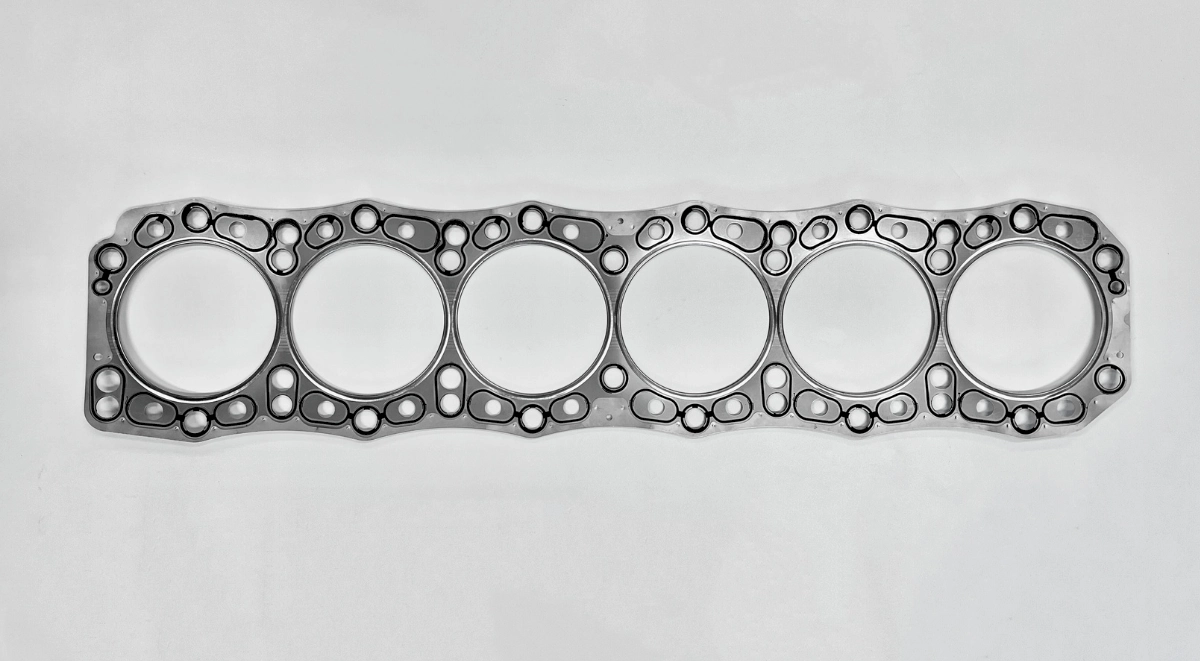

Our client, a marine engine specialist from Germany, operates in the marine engine sector. They have a long-standing relationship with MJ Gasket and have entrusted us with several challenging projects over the years. In this case, they required a highly customized inline 6-cylinder head gasket for a marine engine and requested MJ Gasket to duplicate the head gasket for them.

What challenges did the client face?

This project presented significant challenges due to the technical complexity and customization needed to manufacture a high-technique-made gasket. This customized head gasket is for a marine inline 6-cylinder engine, so it is large and requires high precision. The task became even more demanding because of the specific material composition required. This customized head gasket had to be manufactured using multi-layer steel (MLS) combined with rubber bonding.

- Size and Complexity:

The head gasket had to be large and precisely made for an inline 6-cylinder engine, making it difficult to ensure a perfect fit and reliable performance. - Material Composition:

The head gasket required multi-layer steel (MLS) with rubber bonding, a composite material offering both strength and flexibility for optimal performance in high-pressure environments. - Limited Supplier Availability:

Very few gasket manufacturers have the capability to handle such specialized material combinations and large-scale precision manufacturing. Consequently, finding a supplier with the required expertise and technology to fulfill this complex request was a major challenge.

How did this customized head gasket project begin?

The project began with the client sending detailed pictures of the head gasket, highlighting key specifications. To ensure precision, they later provided a physical sample, allowing MJ Gasket to thoroughly evaluate the gasket’s dimensions and materials before proceeding with the quote.

MJ Gasket Team evaluates and offers the best customized head gasket solution

MJ Gasket developed a bespoke cylinder head gasket using multi-layer steel (MLS) with advanced rubber bonding. After evaluating the head gasket’s materials of steel and rubber and the manufacturing process, we used advanced manufacturing techniques to produce this customized gasket.

- Multi-layer Steel (MLS):

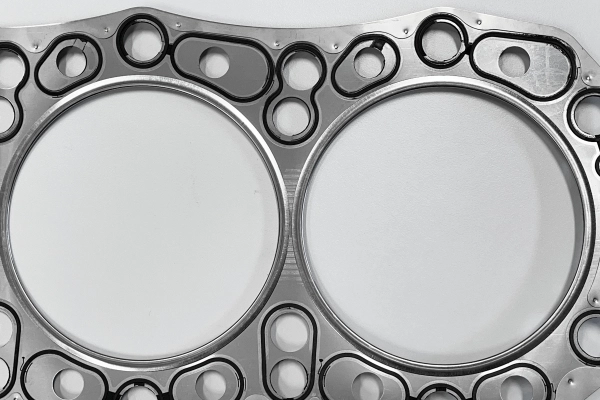

Based on the sample, we used high-grade steel and applied precise laser welding techniques. - Rubber Bonding:

Rubber is ideal for sealing due to its elasticity. Our technique ensured that the rubber was securely bonded to the steel while maintaining a clean appearance, with no excess rubber overflow—an aspect that distinguishes MJ Gasket from other manufacturers. - Precision Engineering:

We used CNC machines to create precise details, such as water and oil holes. This ensured the dimensions of our head gasket exactly matched the original one, and we also precisely measured the bore size after installing the fire ring.

|

|

|

How to check the quality of this customized head gasket?

The customized head gasket underwent rigorous quality control checks by MJ Gasket to ensure it met the client’s specifications. We also provided a sample to the client. Once the client approved the sample, we proceeded to mass production, and the finished gaskets were delivered to the client.

Let’s work together!

If you’re seeking a customized head gasket solution for your specific engine needs, MJ Gasket is here to help. Our professional team delivers tailored solutions with added services to meet your exact requirements. Contact us today to discuss your project!

To streamline the evaluation process and reduce communication time, please send detailed pictures of your gaskets to gasket@mj-deyi.com.tw.