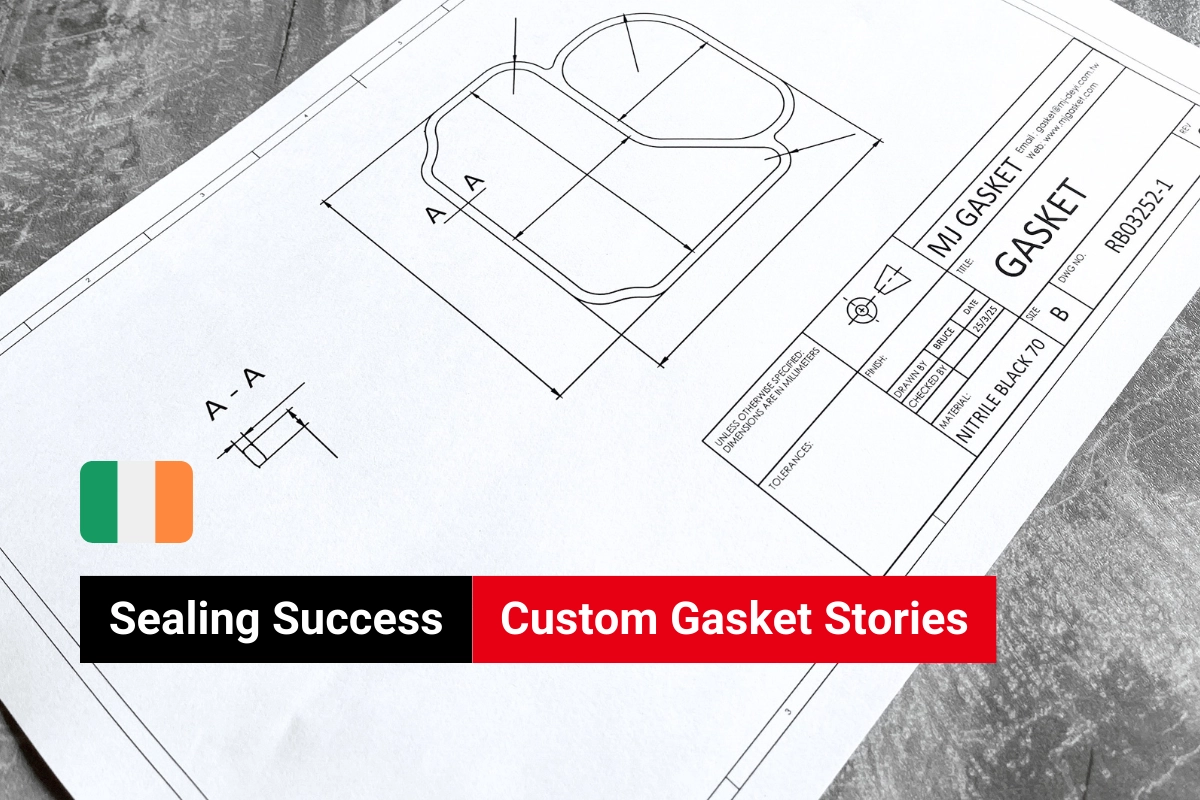

Case ID: MJ-CS-23-002

A turbo specialist from Canada reached out to us with a request for a sandwich-type turbo gasket for a Waukesha engine. This gasket features a double-jacket shell construction with filler materials in between, a design known for its durability and ability to withstand high-pressure, high-temperature environments.

Table of Contents

Sandwich-Type Turbo Gasket Specifications and Client Requirements

The client provided the Waukesha part number and specified stainless steel for the outer layers, paired with a graphite filler. Stainless steel offers strength and corrosion resistance, while graphite provides excellent thermal resistance and sealing. This combination ensures reliable performance under extreme temperatures and pressure.

OEM Sample Analysis and Findings for the Sandwich-Type Turbo Gasket

Upon evaluating the OEM sample, our team found that the original sandwich-type turbo gasket used a non-asbestos filler instead of the requested graphite. This choice differed from the client’s material preference, revealing a notable discrepancy between the client’s request and the OEM specification.

Graphite offers better heat resistance and performs well at higher temperatures, while non-asbestos fillers provide adequate sealing but are less effective in extreme heat. This difference explains the client’s preference for graphite.

Why Is the Choice of Filler Material Important for Sandwich-Type Turbo Gasket?

The choice of filler material is crucial for sandwich-type turbo gasket due to the extreme conditions they face. Positioned between the turbocharger and the exhaust manifold, these gaskets must withstand intense pressure, high temperatures, and thermal cycling. A properly selected filler material ensures reliable sealing, durability, and optimal performance, which is why clients often request specific materials tailored to their operational needs.

Which Filler Material is Better for Sandwich-Type Turbo Gasket: Graphite or Non-Asbestos?

When selecting the most suitable filler material for sandwich-type turbo gasket, it is essential to consider the operating environment and performance requirements. Turbo gaskets are typically exposed to extreme temperatures and high-pressure conditions, particularly as they are positioned between the turbocharger and the exhaust manifold. The two primary options for filler materials are graphite and non-asbestos, each offering distinct advantages and limitations.

Graphite is known for its superior thermal conductivity, excellent sealing properties, and high resistance to temperature and pressure. These attributes make it ideal for high-performance applications where durability and heat resistance are critical. On the other hand, non-asbestos fillers provide a cost-effective solution with good chemical resistance and reliable performance under moderate conditions. They are composed of synthetic fibers and rubber binders, making them suitable for less extreme applications.

To better understand the differences, here’s a detailed comparison:

| Feature | Graphite Gaskets | Non-Asbestos Gaskets |

| Material Composition | Made from expanded graphite, often reinforced with stainless steel or other metals for strength. | Composed of synthetic fibers, aramid fibers, and fillers, bonded with rubber. |

| Temperature Resistance | Excellent resistance, typically up to +450°C (842°F) or higher in certain formulations. | Moderate to high resistance, generally up to +300°C (572°F) depending on the blend. |

| Pressure Resistance | High pressure resistance, suitable for extreme conditions like turbochargers and exhaust systems. | Good pressure resistance, suitable for general industrial applications. |

| Sealing Performance | Superior sealing properties due to its compressibility and conformability to flange surfaces. | Reliable sealing for moderate conditions but less conformable compared to graphite. |

| Thermal Conductivity | High thermal conductivity, making it effective in heat transfer applications. | Lower thermal conductivity compared to graphite. |

| Chemical Resistance | Excellent chemical resistance to a wide range of aggressive chemicals, including acids and alkalis. | Good chemical resistance but may be less effective against certain harsh chemicals. |

| Durability and Longevity | Highly durable under thermal cycling and extreme temperatures. | Durable in moderate conditions but may degrade faster under high thermal stress. |

| Cost | Generally more expensive due to high-performance characteristics. | More cost-effective, suitable for a wide range of industrial applications. |

| Applications | Ideal for high-temperature, high-pressure environments like turbo gaskets, exhaust systems, and heat exchangers. | Commonly used in industrial piping, compressors, pumps, and general sealing applications. |

The choice between graphite and non-asbestos fillers largely depends on the specific requirements of the sandwich-type turbo gasket application:

Choose Graphite if the gasket is expected to endure extremely high temperatures, high pressure, and aggressive chemicals. Its excellent thermal conductivity and sealing properties make it the superior choice for turbochargers and exhaust systems.

Choose Non-Asbestos if the application involves moderate temperatures and pressures where cost efficiency is a priority. It is also a good alternative for general industrial applications with less severe operating conditions.

Our Expertise in Custom Sandwich-Type Turbo Gasket Solutions

As in this case, we highlighted the differences between graphite and non-asbestos fillers, providing the client with tailored options to meet their needs. With our extensive experience, we specialize in crafting high-quality sandwich-type gaskets, particularly for turbos, providing exceptional sealing and endurance.

Not Just This! Additional Service: Customized Laser Marking

We go beyond just delivering high-quality gaskets. For this client, we also provide laser marking services, personalizing the turbo gasket with their brand name and part numbers. This enhances brand identity and ensures each gasket is easily traceable, meeting the client’s specific requirements.

Let’s collaborate!

If you’re in need of a custom gasket solution, MJ Gasket is ready to assist. Our expert team provides tailored solutions with additional services to meet your specific needs. Get in touch with us today to discuss your project!

To speed up the evaluation process and minimize communication time, please send detailed pictures of your gaskets to gasket@mj-deyi.com.tw.