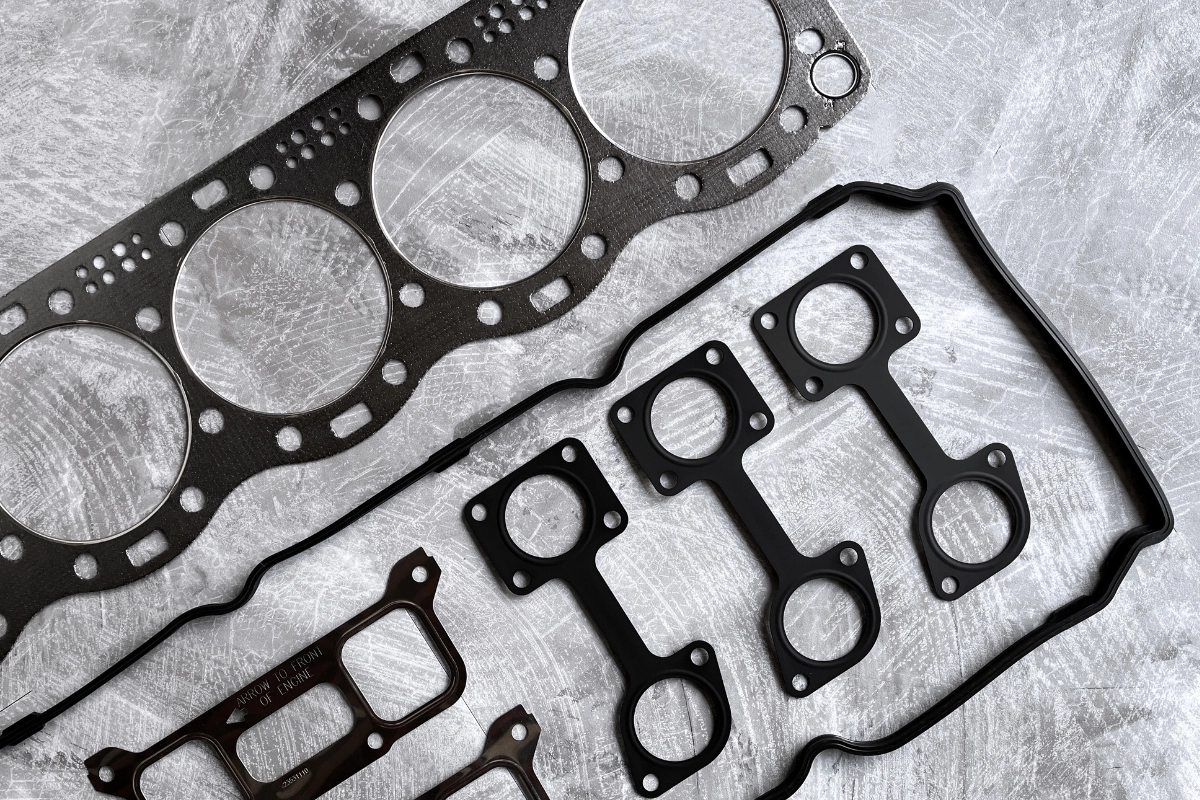

MJ Gasket specializes in producing various engine gaskets. We offer high-quality gaskets for plate heat exchangers. Our gaskets are suitable for engine rebuilds, enabling efficient overhauls. We also provide gasket replacements to extend the lifespan of engines.

Application

MTU 2000/MTU 4000/MTU 183/MTU 396

Detroit Diesel S60

Caterpillar C18 / C32

What is PHE gasket?

A PHE (Plate Heat Exchanger) is a type of heat exchanger that consists of several parallel plates to a series of channels for fluids to flow between them for heat and cool exchange.This has a major advantage over a conventional heat exchanger in that the fluids are exposed to a much larger surface area because the fluids are spread out over the plates.

The PHE gasket (plate heat exchanger gasket) seal the channels and direct the fluids into channels where the fluids exchange will work. There are two types of PHE gasket (plate heat exchanger gasket) – Diagonal Flow Gasket and Parallel Flow Gasket. Usually, their materials are elastomer (rubber), mostly NBR, EPDM, and FKM.

What engine models does MJ GAKSET provide gaskets for MTU’s Plate Heat Exchangers?

At MJ Gasket, with over 40 years of expertise in heavy-duty engine gaskets, we specialize in high-quality Plate Heat Exchanger gaskets. Our commitment to the perfect fit is exemplified in our mission. Guided by the vision ‘Develop Nonstop,’ we stay curious, embracing new products and knowledge.

The following introduces what MJ Gasket can offer.

Plate Heat Exchanger Gaskets for MTU 4000 Engines

The MTU 4000 series is a range of four-stroke industrial engines with rated outputs between 0.75 and 4.3 MW. They are diesel engines and were the world’s first series-produced engines with common rail injection. With outputs of between 720 and 4,300 kW, they have the ability to power luxury yachts as well as haul trucks – and even power generators or trains.

Below is the aftermarket MTU 4000 PHE Gasket, provided by MJ Gasket.

Plate Heat Exchanger Gaskets for MTU 2000 Engines

The MTU 2000 series is a range of diesel generator sets that have proven themselves over six generations. The latest generation pushes the boundary even further with major engine components optimized, intelligently combined, and perfectly adapted to one another. The MTU 2000 series offers excellent load acceptance, accepting extremely high load steps without significant frequency and voltage deviations. It’s also the best-selling MTU series, with over 65,000 engines delivered in the past 25 years.

Below is the aftermarket MTU 2000 PHE Gasket, provided by MJ Gasket.

Plate Heat Exchanger Gaskets for MTU 183 Engines

The MTU 183 series is MTU’s high-selling engine, with sales of over 10,000 units. It now produces 970 kW (1320 hp) of power in its yacht version, making it substantially more attractive for yachts of up to around 25 meters.

Below is the aftermarket MTU 183 PHE Gasket, provided by MJ Gasket.

Plate Heat Exchanger Gaskets for MTU 396 Engines

The MTU 396 series engines were the logical further development of the MTU Series 396 engine. They are used in a broad range of applications and have gained vast experience with more than 15,000 Series 396 engines.

Below is the aftermarket MTU 396 PHE Gasket, provided by MJ Gasket.

Plate Heat Exchanger Gaskets for MTU/ Detroit Diesel 60 Engines

Plate Heat Exchanger Gaskets for CAT C18 / C32 Engines

MJ Gasket’s dedication to quality has led to the production of high-performing gaskets that are highly demanded in the market. Our superior gaskets have supported numerous customers in expanding their businesses. Our commitment to quality is highlighted by the prestigious ISO 9001:2015 certification we’ve maintained for seven years, validating us as a recognized gasket manufacturer by GFA. Please contact us for more information.