Press-in-Place (PIP) seals are indispensable for a wide range of industrial applications. Discover the basic understanding, materials, and applications of PIP seals with MJ Gasket’s reliable and comprehensive solutions.

Table of Contents

Basic Understanding of PIP Seals

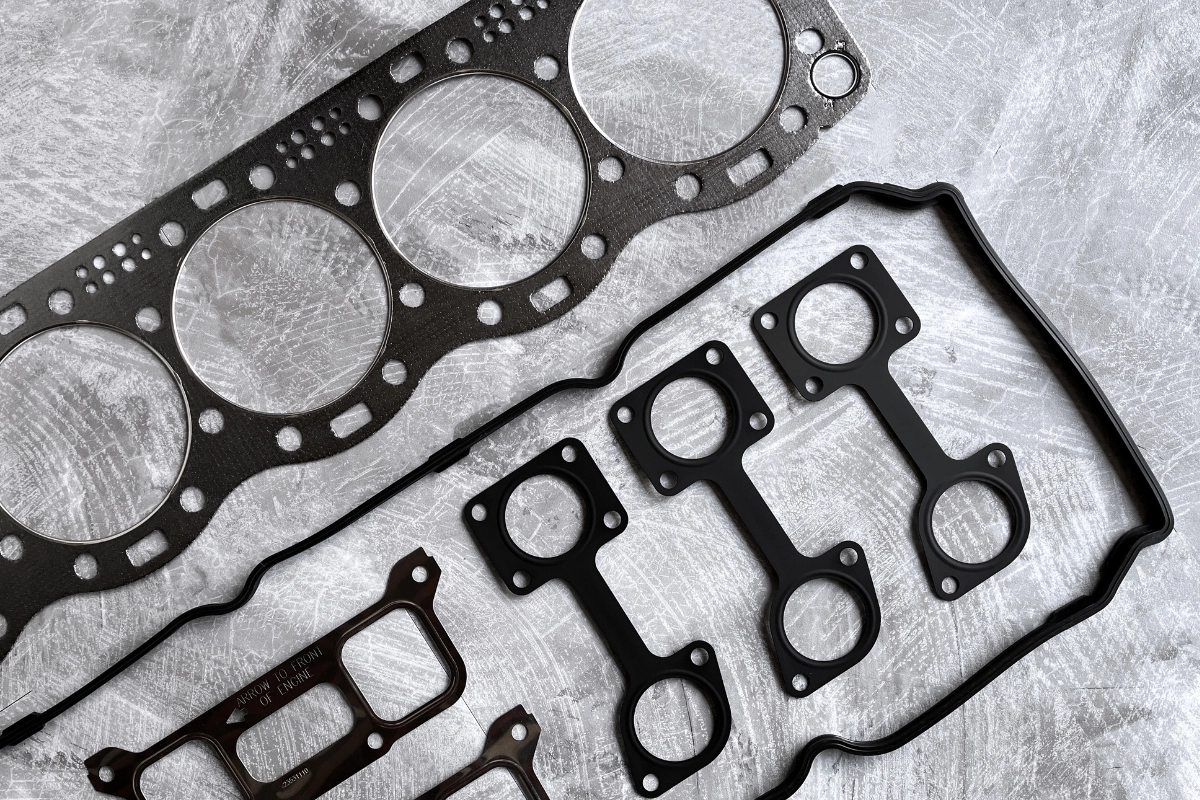

Press-in-Place (PIP) seals are indispensable components in heavy-duty diesel engines, where reliable sealing solutions are crucial for optimal performance and longevity. These seals are engineered to withstand the harsh operating conditions typically encountered in diesel engines, including high temperatures, pressures, and vibrations. PIP seals play a vital role in sealing critical components such as cylinder heads, valve covers, oil pans, and coolant systems, ensuring the integrity of the engine and preventing costly leaks and downtime.

Common Materials Used in PIP Seals

Press-in-Place (PIP) seals are commonly used in various industrial applications due to their ability to provide a secure and reliable sealing solution. These seals are typically made from elastomeric materials, each offering unique properties to meet specific application requirements. Let’s explore some of the common elastomeric materials used in PIP seals:

- FKM (Fluoroelastomer):FKM is a synthetic rubber known for its excellent resistance to heat, chemicals, and oils. It is often used in PIP seals for applications where high temperature resistance and chemical compatibility are crucial, such as in automotive, aerospace, and industrial settings.

- NBR (Nitrile Butadiene Rubber):NBR is a type of synthetic rubber that offers good resistance to oils, fuels, and chemicals. PIP seals made from NBR are commonly used in applications where resistance to petroleum-based fluids is important, such as in automotive seals, hydraulic seals, and O-rings.

- HNBR (Hydrogenated Nitrile Butadiene Rubber): PIP seals made from HNBR offer increased durability and resistance, making them ideal for demanding industrial environments where high temperatures, pressures, and vibration conditions are encountered.

Different Application of PIP seals that MJ Gasket offer

At MJ Gasket, with over 40 years of expertise in heavy-duty engine gaskets, our commitment to the perfect fit is exemplified in our mission. Guided by the vision ‘Develop Nonstop,’ we stay curious, embracing new products and knowledge. Explore our best-selling PIP Gaskets with below different applications

1. Valve Cover Gasket

2. Oil Cooler Gasket

3. Oil Pump Gasket

4. Water Pump Gasket

5. Turbo Acturator Gasket

6. Other Application

How MJ ensure the performance of PIP seals

As you can see on the below picture, PIP Seals features retention ridges that faciliate installation. Additionally, they have small contact point design, which requires less flange and ensures good sealing performance. Therefore, it is crucial to manufacture precise gaskets that fit the dimensions of these seals accurately.

MJ Gasket is proud to share with you our reliable measurement partners, the Keyence IM-7000 Image Dimension Measurement System and 3D Optical Profilometer VR-6200. These instruments not only provides accurate measurement data to ensure that our manufactured samples match OEM samples, but it also eliminates human-induced measurement deviations, offering professional and precise results.

The Keyence IM-7000 & VR-6200 are capable of accurately measuring PIP seals thanks to its advanced image measurement technology. It can capture and analyze the complex details of the seals, including the retention ridges and small contact points, ensuring that the final products meet the highest quality standards.

Please refer to this article introducing our professional and precise equipments, also there’s another video here showing you how our high-quality PIP seal can perfectly match the device.

Contact Us to get the details of how to get your samples, If you are looking for other PIP Sealing gaskets for different engine models, Contact Us now!

MJ Gasket’s dedication to excellence, backed by over four decades of experience, has resulted in high-quality gaskets that are now a promising product in the market. We’ve assisted numerous customers in expanding their businesses by providing top-notch gaskets. Our commitment to quality is underscored by the prestigious ISO 9001:2015 certification held for seven consecutive years, making us a certified gasket manufacturer recognized by GFA. Contact us for details.