An O ring for fuel injectors is a small seal in a ring shape that is crucial in preventing fuel leaks in the fuel injection system. These O-rings play a critical role in delivering the right amount of fuel to the engine, ensuring that the fuel is delivered precisely without any leakage.

Made of rubber or other synthetic materials, O rings for fuel injectors are designed to be resistant to the harsh chemicals and high temperatures present in fuel systems. These materials are also durable, but over time, they can wear out or become damaged, leading to engine problems and fuel leaks.

Replacing the O-rings for fuel injectors is an essential maintenance task that can help to prevent expensive repairs in the future and ensure the proper functioning of the fuel system. It is recommended to have the O-rings inspected and replaced as needed as part of regular vehicle maintenance to avoid any potential safety hazards.

Table of Contents

What types of materials are used in o ring for fuel injectors?

There are several types of fuel injector O-rings available on the market, including:

- Viton : These are made of a synthetic rubber material that is resistant to high temperatures and chemicals, making them ideal for use in fuel injector applications.

- Nitrile: These are made of a durable and economical rubber material that can withstand exposure to oils and fuels.

- Silicone: These are made of a flexible and heat-resistant material that can withstand high temperatures and pressure, making them ideal for use in high-performance engines.

- Fluorosilicone: These are made of a high-performance material that combines the flexibility of silicone with the chemical resistance of fluorocarbon, making them ideal for use in harsh fuel environments.

The type of O-ring needed will depend on the specific application and the requirements of the engine or fuel system.

Where is the location for installing the o ring for fuel injectors?

The location of the fuel injector O-ring installation can vary depending on the specific engine and fuel injection system. Generally, fuel injector O-rings are installed at the base of the fuel injector, where the injector is inserted into the fuel rail or fuel delivery system.

To access the fuel injector O-rings, the fuel rail may need to be removed, and the fuel injectors may need to be disconnected from the fuel lines. It is important to follow the manufacturer’s instructions and use the correct tools to ensure proper installation of the O-rings and prevent damage to the fuel system.

It is recommended to have a professional mechanic or technician handle fuel injector O-ring installation, as it can be a complex process and requires specialized knowledge and tools.

When is it necessary to replace the o ring for fuel injectors?

Fuel injector O-rings should be replaced if they become worn or damaged, or if they begin to leak. Signs of a faulty fuel injector O-ring may include fuel leaks, reduced engine performance, rough idling, or difficulty starting the engine.

It is also recommended to replace the fuel injector O-rings as part of regular vehicle maintenance, typically every 60,000 to 100,000 miles, depending on the manufacturer’s recommendations.

Regular replacement can help to prevent fuel leaks and ensure the proper functioning of the fuel injection system, which can help to prevent costly engine repairs in the future.

Common causes of fuel injector O-ring failure include.

- Age and wear: Over time, fuel injector O-rings can become brittle and cracked, leading to failure.

- Exposure to heat and chemicals: The fuel injector O-rings are exposed to high temperatures and chemicals in the fuel, which can cause them to break down and fail.

- Contamination: Dirt and debris can get trapped between the fuel injector and O-ring, causing the O-ring to become damaged or fail.

- Incorrect installation: Improper installation of the O-ring, such as not using the correct torque specifications or over-tightening the fuel injector, can cause the O-ring to fail prematurely.

- Using the wrong type of O-ring: Using a fuel injector O-ring that is not compatible with the specific fuel injection system can cause it to fail. It is important to use the correct type and size of O-ring recommended by the manufacturer.

O-rings for fuel injectors play a crucial role in preventing leaks, which can lead to dangerous conditions for drivers and passengers. Leaking fuel injectors are not common, but it’s important to be aware of the signs so you can address the issue promptly.

Some common symptoms of leaking fuel injectors include increased fuel consumption, poor and shaky idling, gasoline smells, hard starts, bad emission performance, thinning oil, and hydro locking. If you notice any of these symptoms, it’s important to have your vehicle inspected by a professional mechanic as soon as possible to determine if the O-ring for the fuel injector needs to be replaced.

Ignoring the signs of a leaking fuel injector can lead to engine damage and even pose a fire risk. Don’t take any chances when it comes to your vehicle’s safety and performance – address any potential issues with fuel injectors and O-rings promptly.

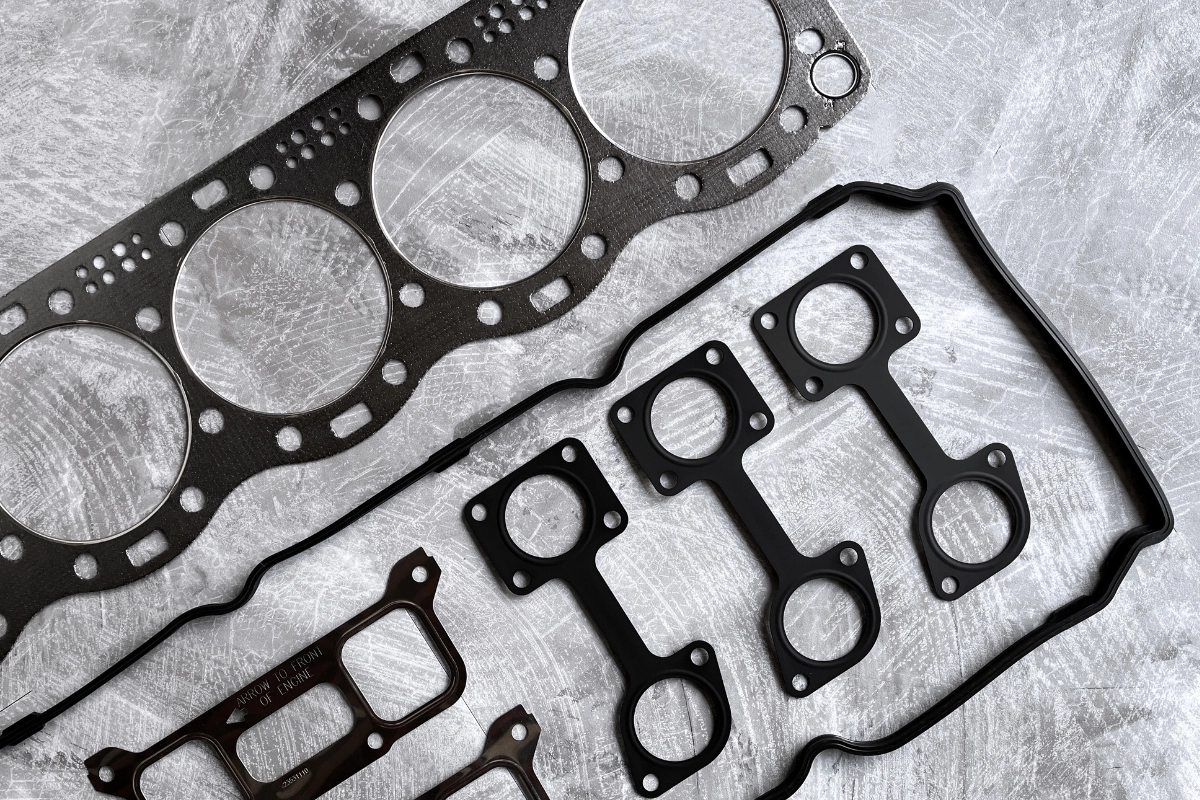

MJ Gasket is currently seeking those who are in need of heavy-duty engine gaskets and seals.

MJ Gasket is currently selling high-quality fuel injector O-rings. These O-rings are made from durable materials and are designed to withstand the harsh conditions of the fuel injection system. They are engineered to provide a reliable and long-lasting seal, ensuring that fuel is delivered properly to the engine.

Our engine gaskets and seals are designed to meet or exceed OEM specifications, ensuring a proper fit and function. They are available in a variety of sizes and types to fit a wide range of fuel injection systems.

Next is the diesel engine gasket kit and fuel injector o ring that MJ Gasket can provide. The content includes a simple introduction to the engine brand and fuel injector, as well as links to reference websites and YouTube. If you need a diesel engine gasket and seal, please feel free to contact us.

Caterpillar fuel injector o rings

Caterpillar Inc. manufactures diverse engines, including industrial, diesel, and gas engines for various sectors like construction and agriculture. They meet stringent emissions standards and are known for efficiency and reliability. Caterpillar also produces engines in China for different markets, ensuring global reach and technological adaptability.

About Caterpillar fuel injector:Worn injectors can reduce engine efficiency, shorten component wear life and result in poor emissions performance. Any of these can increase your operating costs. Cat injectors deliver up to 3X more wear life. Longer injector life means lower operating costs and more money in your pocket. Learn more.

Cummins fuel injector o rings

Cummins Inc. is an American multinational corporation that designs, manufactures, and distributes engines, filtration and power generation products.Cummins also services engines and related equipment, including fuel systems, controls, air handling, filtration, emission control, electrical power generation systems, and trucks.

About Cummins fuel systems:Cummins is renowned for its expertise in fuel systems, backed by over 80 years of experience. The company operates advanced facilities in Columbus, Indiana; El Paso, Texas; and Juarez, Mexico, producing and remanufacturing unit injector and common rail systems. Cummins’ new product line supports engines from 6 to 78 liters, offering industry-leading technology, specialized handling for diverse applications, and integrated solutions to enhance engine performance and fuel efficiency. The remanufacturing business delivers fully reconditioned products for engine remanufacturing and field service needs. Learn more.

Detroit Diesel fuel injector o rings

Detroit Diesel Inc. produces heavy-duty engines like the DD5™, DD8™, DD13®, DD15®, and DD16® for commercial trucks. These engines are renowned for their durability, power, and fuel efficiency, serving various on-highway and vocational applications. They also offer legacy engines and components for diverse industrial needs.

Here are some videos related to Fuel Injectors, shared for your reference. Perfect for anyone interested in getting insights or learning more about them.

Navistar fuel injector o rings

Navistar Inc. specializes in producing engines like the International A26, Cummins, and their own N series for trucks and buses. Their engines are recognized for power and efficiency, serving various transportation and vocational needs. Navistar’s integration with Traton enhances their global presence and technological innovation in engine manufacturing.

Here are some videos related to Fuel Injectors, shared for your reference. Perfect for anyone interested in getting insights or learning more about them.

Volvo fuel injector o rings

Volvo Trucks produces efficient diesel engines like the D11, D13, and D16, known for their power and fuel efficiency. The D13 engine, for instance, offers a balance of performance and efficiency, suitable for a wide range of applications. These engines are part of Volvo’s commitment to durable, high-quality powertrains for the commercial trucking industry.

Here are some videos related to Fuel Injectors, shared for your reference. Perfect for anyone interested in getting insights or learning more about them.

As a provider of automotive and industrial gaskets and seals, MJ Gasket not only offers high-quality fuel injector seals, but also a wide range of other products.With a focus on durability and reliability, our products are a top choice for professionals and automotive repair shops alike.

If you are looking for other fuel injector O-rings for different brands and engine models, please send us the OEM numbers, or contact us by email or the button below.