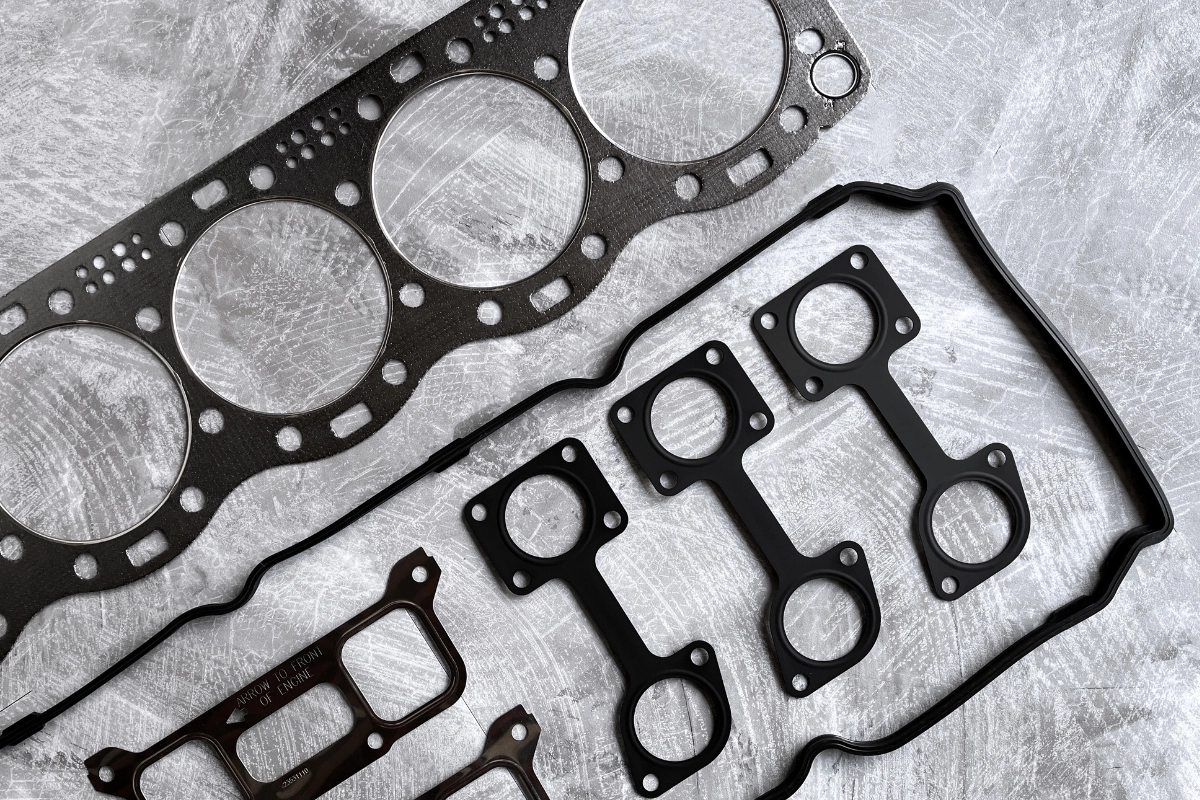

In MJ, we could provide our customers various material of head gasket. Different situation environment need different material. One of the most commonly used materials for manufacturing cylinder head gaskets is GRAPHITE.

Rest see as below:

Best aftermarket head gasket

- Composite graphite – see example 4299098 of Cummins

- Metal bonded with rubber – see example 5240161580 of MTU

- Multi-layer steel – see example A4720161320 of Detroit Diesel

- Sandwich type – see example 7E8028 of Caterpillar

We don’t really do paper head gasket, we more focus on hard materials.

Function of head gasket

One of the most important gaskets in your engine, the head gasket is designed to seal the cylinders’ firing pressure and prevent engine oil from leaking into the cylinders. The position of head gasket is between the engine block and the cylinder head.

Applications

- Caterpillar – C9/C10/C12/C13/C15/3500

- Cummins – QSK19/KT50/QSK45/QSK45G/ QSK60/ISB/ISX15/QSK78

- Detroit Diesel – S60 / DD15

- MTU – Series 60, Series 396, Series 2000, Series 4000

- Volvo – D12/D13

- Navistar – MAXXFORCE 7/DT466

- Paccar – MX-13, MX-11