Fuel injector seals play a critical role in the performance and efficiency of your car’s engine system. They prevent fuel and air leakage while ensuring that the fuel is delivered to the combustion chamber without any loss or wastage. In this article, we will explore fuel injector seals in more detail, including how to check and rebuild them if needed, common symptoms and causes of failure, how to prevent them, and how fuel injector kits aid in rebuilding.

Table of Contents

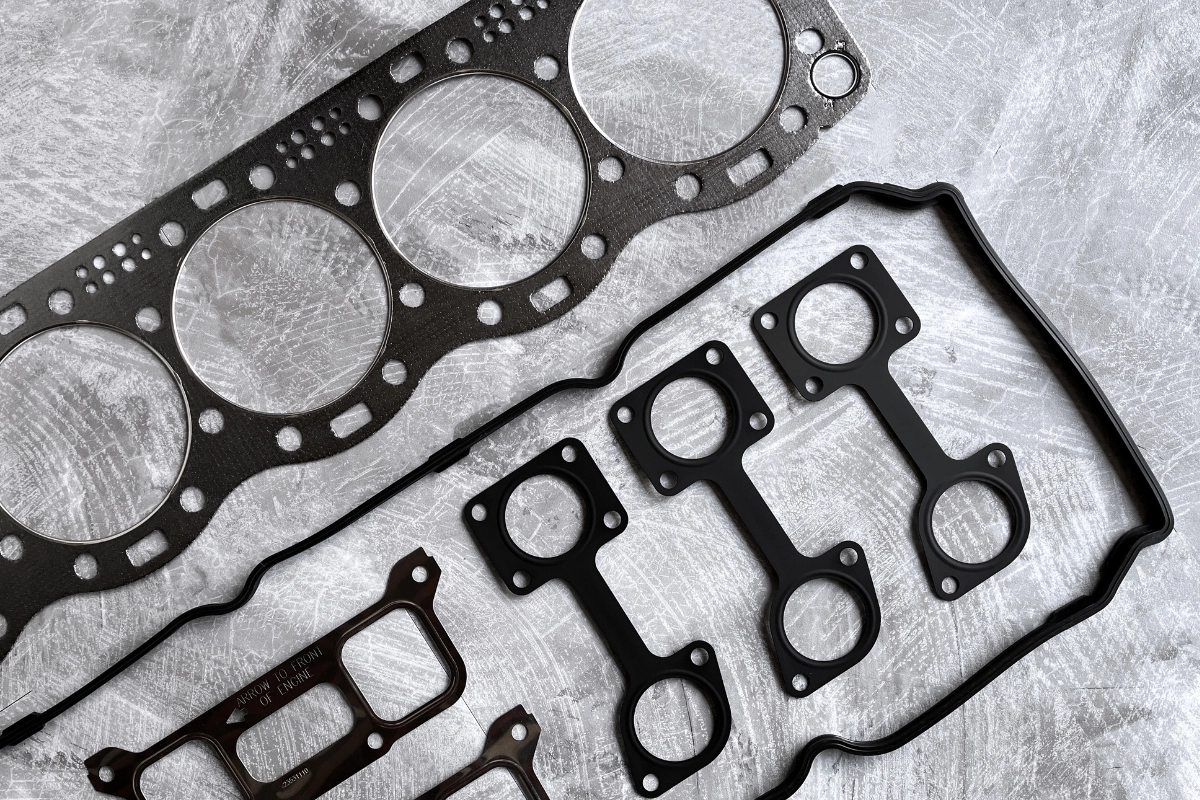

What are Fuel Injector Seals?

Fuel injector seals are small but essential components of your engine system. They are made of high-temperature resistant rubber or silicone and are located between the fuel injector and the cylinder head. These seals create a tight seal between the fuel injector and the cylinder head, preventing fuel and air leakage. They also keep air from entering the fuel system, which could affect the air-fuel ratio and cause engine problems.

Over time, fuel injector seals can wear out, crack, or harden, losing their sealing ability. This can result in fuel and air leakage, which can cause poor engine performance, increased emissions, and fuel consumption. Hence, regular inspection and maintenance of fuel injector seals are critical to avoid any damage or failure.

Checking and Replacing Fuel Injector Seals

Checking Fuel Injector Seals

In order to ensure that your fuel injector seals are in good condition, there are a few steps you can take. First, it’s important to visually inspect the seals for any signs of damage or wear. This can include cracks, tears, or other visible defects. If you notice any of these issues, it’s important to address them right away, as damaged seals can lead to fuel leaks and other problems.

In addition to a visual inspection, you may also want to consider performing a leak test to check the integrity of your fuel injector seals. One simple way to do this is to spray some soapy water around the base of the fuel injector while the engine is running.

If there is a leak in the seal, you should see bubbles forming as the soapy water is drawn into the area where the fuel is leaking out.

By taking the time to check the condition of your fuel injector seals, you can help ensure that your vehicle is running smoothly and efficiently, while also avoiding potentially costly repairs down the line.

Rebuilding Fuel Injector Seals

To replace the fuel injector seals, you need to remove the fuel injectors from the engine. This may require disconnecting some wires, hoses, or clips. You should also relieve the pressure from the fuel system before removing the injectors. Once you have removed the injectors, you can pull off the old seals with a pair of pliers or a screwdriver.

You should clean the injectors and the cylinder head with a rag or a brush to remove any dirt or debris. Then you can install new seals on the injectors by pushing them into place with your fingers or a socket. You should lubricate the seals with some engine oil or grease to make them easier to install and seal better. After installing new seals, you can reinstall the injectors on the engine and reconnect everything.

Common Symptoms and Causes of Fuel Injector Seal Failure

Fuel injector seal failure is a common issue that can cause a variety of symptoms, indicating a need for either maintenance or replacement. These symptoms may include a rough idle or misfire, reduced power or acceleration, poor fuel economy, increased emissions, a fuel smell or smoke coming from the exhaust, and a fuel leak under the hood or on the ground.

There are several reasons why fuel injector seal failure may occur. One of the most common is aging or deterioration of the seal material, which can cause the seal to become brittle and crack over time. Exposure to extreme heat or cold can also cause the seal to degrade, leading to eventual failure. Contamination or corrosion of the seal surface can also cause problems, as can improper installation or alignment of the seal. Over-tightening or loosening of the injector bolts can also contribute to fuel injector seal failure. We also wrote an article about 8 Types of Materials Used for Fuel Injector Seals for your reference.

Overall, it is important to keep an eye on the symptoms of fuel injector seal failure and take appropriate action when necessary. Regular maintenance and inspection of the fuel injector system can help to prevent seal failure and prolong the life of your vehicle.

Preventing Fuel Injector Seal Failure

To prevent fuel injector seal failure, you should follow the recommended maintenance schedule of your vehicle. Regular inspection of fuel injectors and seals is critical to detect any damage or wear early.

Other measures to prevent fuel injector seal failure include using good quality fuel that meets your vehicle’s specifications, replacing your fuel filter regularly to prevent dirt and debris from entering the fuel system, avoiding using additives or cleaners that may damage the seal material, and checking your engine oil level and quality frequently to prevent oil dilution or contamination.

How Fuel Injector Seal Kits Aid in Rebuilding

A fuel injector seal kit can be invaluable when rebuilding fuel injectors. Here’s how it helps:

- Seal Replacement: Over time, the seals in fuel injectors can degrade due to exposure to heat, fuel, and other factors. A seal kit typically includes all the necessary seals, O-rings, and gaskets needed to rebuild the old ones. This helps ensure proper sealing, preventing fuel leaks, and maintaining optimal injector performance.

- Prevention of Contamination: The seal kit provides new seals to prevent contamination of the fuel injector. Contaminants such as dirt, debris, and old seal material can interfere with the proper operation of the injector or even cause damage. By replacing the seals, you eliminate this risk and ensure clean operation.

- Improved Performance: Proper sealing is crucial for the precise metering of fuel into the engine cylinders. If the seals are worn or damaged, it can lead to issues like fuel leaks, poor fuel atomization, and inconsistent engine performance. Installing a seal kit restores the injector’s ability to deliver fuel accurately, resulting in improved engine performance, fuel efficiency, and emissions control.

- Cost-Effectiveness: Rebuilding fuel injectors with a seal kit is often more cost-effective than purchasing new injectors. It allows you to extend the life of your existing injectors by replacing worn components rather than replacing the entire unit.

- Customization and Compatibility: Seal kits are often available for specific injector models and types, allowing for precise customization and compatibility. This ensures that you get the right seals for your particular injectors, minimizing the risk of fitment issues or performance problems.

Overall, a fuel injector seal kit is a crucial component when rebuilding injectors, as it helps restore proper sealing, prevents contamination, improves performance, and offers cost-effective maintenance options.

What Diesel Fuel Injector Seals and O-rings does MJ offer?

Now you know the importance of diesel injector seals. MJ Gasket provides seals for your engine injector system, and the perfect fit is our final mission.

Our vision is “Develop Nonstop”; we are curious about anything new, including product development and in-depth knowledge.

Below, we are confident to recommend our best-selling Fuel Injector Seal :

Caterpillar – Fuel Injector O-Ring Kit

Prevent fuel leaks in your engine with Caterpillar Fuel Injector O-Ring Kits, available for C10/C12 and 3406E/C11/C13/C15/C16/C18 models.

Detroit Diesel – Fuel Injector Seal Kit

Ensure your Detroit Diesel engine is running smoothly with the right fuel injector kit.

Navistar International High-Pressure Oil Rail Seal Kit

Navistar International High-Pressure Oil Rail Seal Kit, available for DT466/HT570 models.

If you are looking for fuel injector seals for other brands, please visit our List of Fuel Injector Seal Product Pages for more information.

MJ Gasket’s dedication to excellence, backed by over four decades of experience, has resulted in high-quality gaskets that are now a promising product in the market. We’ve assisted numerous customers in expanding their businesses by providing top-notch gaskets. Our commitment to quality is underscored by the prestigious ISO 9001:2015 certification held for seven consecutive years, making us a certified gasket manufacturer recognized by GFA. Contact us for details.