Brakes are one of the most critical components of any vehicle, ensuring safe operation by allowing drivers to control speed and bring the vehicle to a stop when needed. Different types of braking systems exist, with air brakes and hydraulic brakes being the two primary types used in trucks and heavy-duty vehicles. Understanding their differences and applications is essential for maintaining vehicle performance and road safety.

Table of Contents

Air Brakes vs. Hydraulic Brakes: Key Differences

When it comes to braking systems in commercial vehicles, the choice between air brakes and hydraulic brakes depends on various factors such as vehicle size, load capacity, and application. Below are the main differences between air brakes and hydraulic brakes:

Air Brake System:

- Uses compressed air for braking force.

- Commonly found in heavy-duty trucks, buses, and trailers.

- Ideal for long-distance driving and heavy loads.

- Provides more consistent braking performance under high stress.

Hydraulic Brake System:

- Uses brake fluid to transfer force from the brake pedal.

- Common in smaller trucks and passenger vehicles.

- Provides responsive and efficient braking.

- Less effective for extremely heavy loads compared to air brake systems.

Why Are Air Brakes Preferred for Heavy-Duty Trucks?

Air brakes provide reliable stopping power even with minor leaks, unlike hydraulic brakes that rely on fluid pressure. They continuously generate compressed air, preventing brake fade and ensuring durability. This makes them ideal for heavy-duty trucks carrying large loads over long distances, where safety and performance are critical.

Where is the Air Compressor on a Semi-Truck?

The air compressor on a semi-truck is typically located on the engine, usually mounted on the lower side of the engine block. It is driven by a pulley or gear system connected to the engine’s crankshaft or belt drive. In some cases, it may be located near the front of the engine, close to the radiator or fan assembly.

How Does a Semi-Truck Air Compressor Work?

As a company specializing in gaskets and parts for heavy industries, we understand the importance of reliable components. In this article, we will discuss the Air Compressor, a crucial part of air brake systems.

An Air Compressor draws in outside air, compresses it, and stores it in reservoirs to supply the necessary pressure for braking. When the brakes are applied, the compressed air is released to engage the brake chambers, ensuring safe and efficient stopping power. A well-functioning Air Compressor is essential for maintaining consistent brake performance, making it a key component in heavy-duty vehicle safety and reliability.

Bendix Air Compressor

Bendix is the leader in air compressors, with over a century of technological excellence. The Bendix air compressor not only delivers stable air pressure but also prioritizes safety, ensuring reliable brake system performance and enhancing overall driving safety. With high efficiency and low maintenance requirements, Bendix air compressors keep vehicles in optimal condition under various working conditions, making them the top choice in the global heavy-duty vehicle sector.

Bendix Air Compressor BA-921 vs. BA-922

Bendix Air Compressor BA-921 Standard

- Utilizes external cooling, connecting to the vehicle’s engine cooling system to dissipate heat.

- Designed for standard commercial vehicles, including long-haul trucks and buses.

- Features an open structure that allows for easy maintenance and inspections.

- Works well under typical operating conditions, consistently delivering compressed air.

Bendix Air Compressor BA-921 Closed Room

- Uses internal cooling, ideal for vehicles with limited space.

- Suited for harsh environments or dusty areas, preventing contaminants from compromising performance.

- The closed structure requires careful coordination with the vehicle’s cooling system for proper heat dissipation.

- Designed to minimize noise and vibration, making it suitable for applications that demand quiet operation.

- Only accepts natural air intake; using an engine turbocharger as the air source is not allowed.

Bendix Air Compressor BA-922

- Similar to the BA-921 but tailored for specific vehicle models.

- Features a redesigned airflow system that enhances air intake efficiency.

- Built with reinforced components to withstand more demanding conditions.

- Offers increased durability and reduces the likelihood of malfunctions, improving overall vehicle performance.

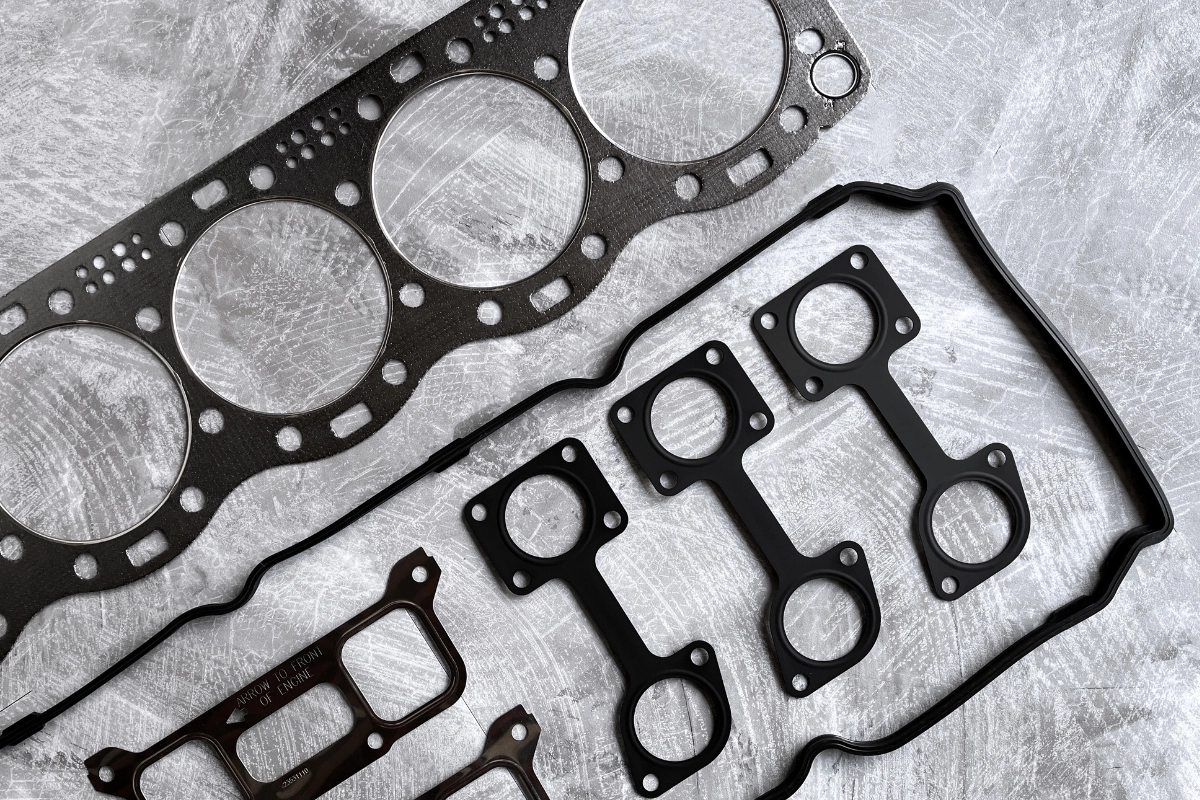

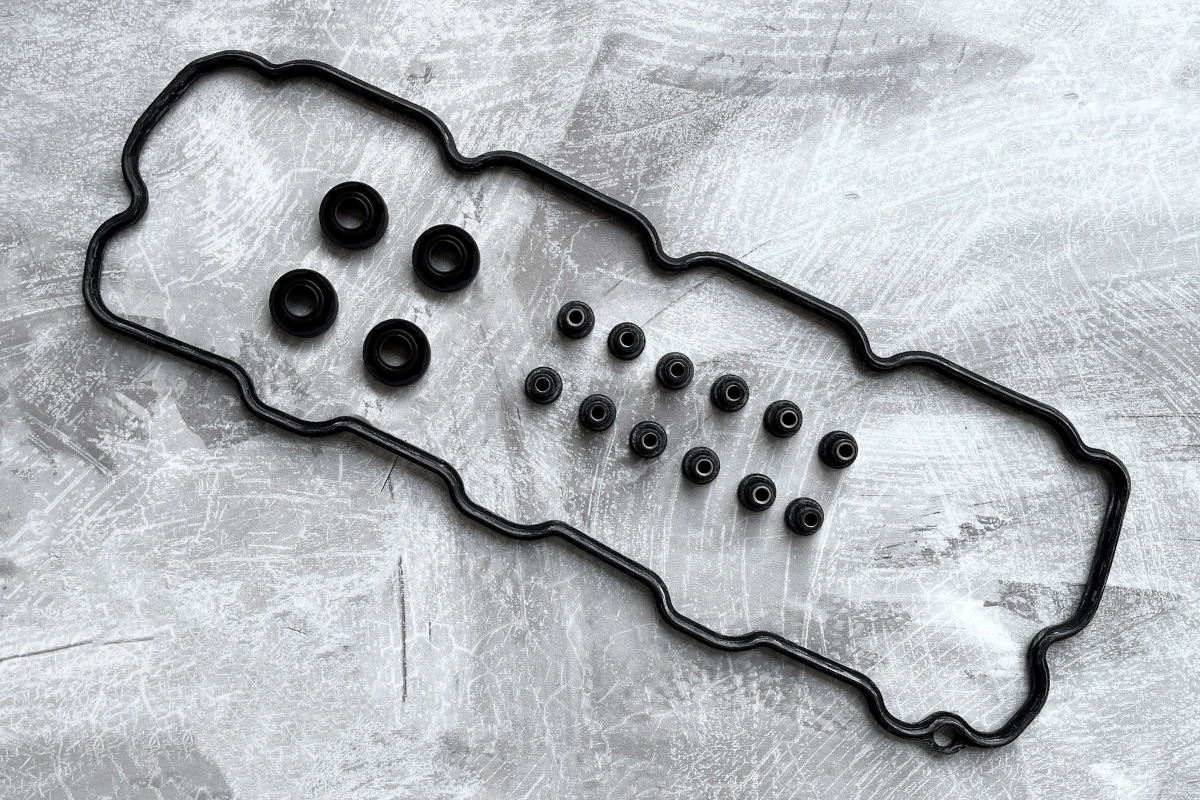

Bendix Air Compressor Rebuild Kit – Aftermarket Solutions

As a trusted gasket manufacturer for heavy industries, MJ Gasket proudly provides high-quality Bendix air compressor rebuild kits to meet demanding applications. Our kits, available for BA-921 Standard, BA-921 Closed Room, and BA-922 models, are cross-referenced with Caterpillar and Detroit Diesel engines, ensuring a reliable solution for fleet operators and maintenance professionals. With precision-engineered sealing components and durable materials, MJ Gasket’s aftermarket solutions offer excellent performance, reliability, and cost-effectiveness.

Bendix Air Compressor Rebuild Kit x Caterpillar Engines

Bendix Air Compressor Rebuild Kit for Caterpillar Engines BA-921 Standard

| Caterpillar Engine Model | Caterpillar ACERT 3126, C7, C9 | Caterpillar ACERT C11, C13, C15, C18 |

| Bendix Air Compressor Model | BA-921 Standard | |

| Bendix Air Compressor Rebuild Kit | 5008558 | 5008558 |

| Bendix Air Compressor Seal Kit (w/ engine seal) |

5012367 | 5012369 |

| Bendix Air Compressor Seal Kit (w/o engine seal) |

5008559 | 5008559 |

Bendix Air Compressor Rebuild Kit x Caterpillar Engines BA-921 Closed Room

| Caterpillar Engine Model | Caterpillar C7, C9, C13, C15, C18 Tier 4 Industrial |

| Bendix Air Compressor Model | BA-921 Closed Room |

| Bendix Air Compressor Rebuild Kit | K023764 |

| Bendix Air Compressor Seal Kit (w/ engine seal) | 5012367 |

| Bendix Air Compressor Seal Kit (w/o engine seal) | 5008559 |

Bendix Air Compressor Rebuild Kit x Caterpillar Engines BA-922

| Caterpillar Engine Model | Caterpillar ACERT C11, C13, C15, C18 |

| Bendix Air Compressor Model | BA-922 |

| Bendix Air Compressor Rebuild Kit | 5014472 |

| Bendix Air Compressor Seal Kit (w/ engine seal) | 5012369 |

| Bendix Air Compressor Seal Kit (w/o engine seal) | 5008559 |

Bendix Air Compressor Rebuild Kit x Detroit Diesel Engines

| Detroit Diesel Engine Model | Detroit Diesel 60 Series (Pre-2007) | Detroit Diesel 60 Series (2007) | Detroit Diesel 60 Series (EGR) |

| Bendix Air Compressor Model | BA-921 Standard | BA-921 Closed Room | BA-922 |

| Bendix Air Compressor Rebuild Kit | 5008558 | K023764 | 5014472 |

| Bendix Air Compressor Seal Kit (w/ engine seal) | 5012371 | 5012371 | 5012371 |

| Bendix Air Compressor Seal Kit (w/o engine seal) | 5008559 | 5008559 | 5008559 |

Ensuring reliable braking performance is crucial for the safety and efficiency of heavy-duty vehicles. If you’re looking for a trusted supplier of air compressor rebuild kits, MJ Gasket is your go-to partner for heavy-duty air compressor solutions.