Explore the world of wide range of air brake compressor gaskets with MJ Gasket, including rubber-coated metal and silicone-lined gaskets. From edge bonded seals to essential components like O-rings and crankcase cover gaskets, we provide reliable sealing solutions for various applications. Trust MJ Gasket for high-quality gaskets backed by over 40 years of expertise.”

Table of Contents

Brief introduction of Air Brake Compressors

The function of an air brake compressor is to generate compressed air that is used to power the braking system in vehicles equipped with air brakes. When the driver presses the brake pedal, the compressed air is released from the compressor’s reservoir and directed to the brake chambers, causing the brake shoes or pads to engage and slow down or stop the vehicle.

Please see more detailed information here for clear and complete understanding.

Understanding the Functionality of Air Brake Compressors Part

As for the air brake compressor gasket, its primary function is to create a reliable seal between the different components of the air brake compressor system. These gaskets are typically located between the cylinder head and the compressor body, as well as between other critical components such as valves and fittings.

The key functions of air brake compressor gaskets include:

- Sealing:Gaskets prevent air leakage from the compression chamber, ensuring that pressurized air remains contained within the system. This is essential for maintaining the efficiency and effectiveness of the compressor.

- Preventing Contamination:Gaskets help to prevent contaminants such as dirt, dust, and moisture from entering the compression chamber. This is important for preserving the quality of the compressed air and protecting the internal components of the compressor from damage.

- Reducing Noise and Vibration:Gaskets can also help to dampen noise and vibration generated by the compressor during operation. By providing a cushioning effect between the different components, gaskets contribute to a smoother and quieter operation.

- Ensuring Proper Compression:Proper sealing provided by gaskets is essential for achieving the desired level of compression within the compressor system. This is necessary for generating the required air pressure for various applications, such as pneumatic tools, air brakes, and air suspension systems.

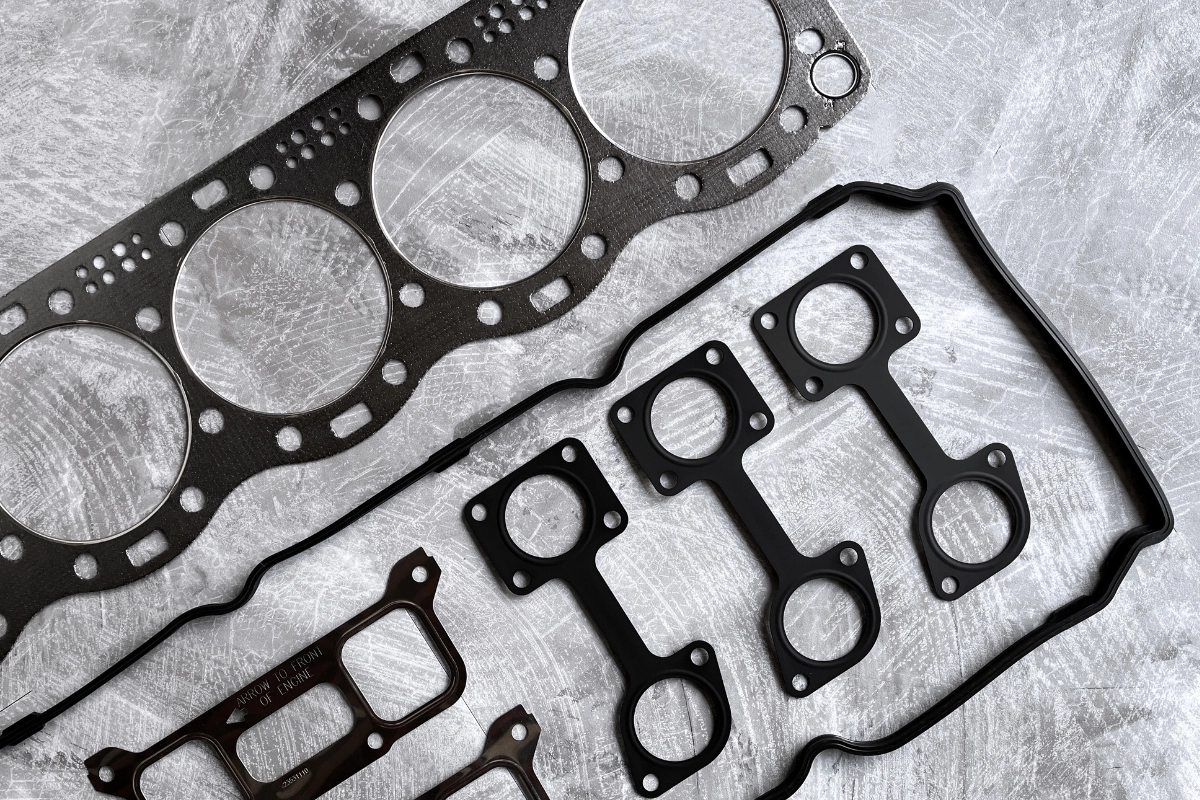

Explore various Gasket Type of Air Brake Compressor Part with different material

1.Kit Compressor Head Gasket

A Kit Compressor Head Gasket typically applies to rubber coated metal or steel with silicone line material. It refers to a set or package containing the necessary components for replacing the head gasket of a compressor. This type of gasket is specifically designed to seal the cylinder head to the compressor body, preventing air leaks and ensuring efficient operation.

The kit typically includes the head gasket itself, along with any additional seals, gaskets, or hardware required for installation. Kit compressor head gaskets are commonly used in maintenance and repair tasks to restore the functionality of compressors in various applications, such as heavy duty truck, industrial, and household settings. Please see the below head gaskets of air compressor #5008558 of Bendix as an example.

2.Edge bonded Gasket of Air Brake Compressor PartsThe edge bonded seal used in air compressor gaskets typically refers to a sealing mechanism where the edges of the gasket are bonded or fused together to create a secure and leak-proof seal.

This type of seal is commonly used in high-pressure applications, such as air compressors, where reliable sealing is critical.

It commonly utilizes steel bonded with rubber, leveraging the durability of steel and the sealing properties of rubber to withstand the demanding conditions of air compressor operation. Please see the below Air Compressor Gasket #1292181 of Caterpillar as an example.

3.Seal Kits of Air Brake Compressor PartsThere are some other essential air compressor gaskets such as crankcase cover gaskets, rear cover gaskets, and O-rings. These components play crucial roles in maintaining the integrity and efficiency of the air compressor system. The crankcase cover gaskets and rear cover gaskets ensure proper sealing of the compressor housing, preventing air leaks and contamination. O-rings, on the other hand, are vital for sealing connections and joints within the compressor, contributing to leak-free operation.

Overall, these seal kits are essential for ensuring optimal performance and reliability of air compressor systems in various applications. Please see the below Air compressor Gasket #2606821 of Caterpillar as an example.

What type of Air Brake Compressor gaskets does MJ Gasket offer?

At MJ Gasket, with over 40 years of expertise in heavy-duty engine gaskets, we specialize in high-quality air compressor gaskets. Our commitment to the perfect fit is exemplified in our mission. Guided by the vision ‘Develop Nonstop,’ we stay curious, embracing new products and knowledge. Explore our best-selling Air Compressor Gasket as below:

For comprehensive air brake compressor parts, trust MJ Gasket’s and commitment to quality.

MJ Gasket’s dedication to excellence, backed by over four decades of experience, has resulted in high-quality gaskets that are now a promising product in the market. We’ve assisted numerous customers in expanding their businesses by providing top-notch gaskets. Our commitment to quality is underscored by the prestigious ISO 9001:2015 certification held for seven consecutive years, making us a certified gasket manufacturer recognized by GFA. Contact us for details.