This article explores the critical role of hydraulic pump gasket materials in enhancing the reliability of hydraulic systems. Covering materials like rubber-coated metal, steal bonded with rubber, and non-asbestos, it emphasizes how material impacts a gasket’s resilience to pressure, temperature, and fluid conditions. Gain insights into the properties and applications of these materials for maintaining leak-free hydraulic operations.

Table of Contents

What is the purpose of hydraulic pump gaskets?

Hydraulic pump gaskets play a vital role in ensuring the efficiency and reliability of hydraulic systems by serving as crucial barriers that prevent hydraulic fluid leakage and the intrusion of contaminants. These seals establish secure barriers between interconnected components and effectively prevent both fluid leaks and contamination, thereby ensuring the hydraulic system’s integrity.

The primary objective is to maintain a consistent seal, ensuring peak performance and system longevity by mitigating the risk of mechanical failures. Additionally, hydraulic pump gaskets contribute to minimizing friction between moving parts, enhancing overall efficiency. As a critical component, the meticulous selection of the right gasket material is essential for achieving optimal performance, longevity, and reliability.

Key consideration in choosing hydraulic pump gaskets Material.

Selecting the appropriate hydraulic pump gasket material involves several key considerations to ensure optimal performance and longevity. Here are four important factors to keep in mind:

1. Fluid Compatibility:

Choose a gasket material that is compatible with the hydraulic fluid. Different hydraulic fluids have varying chemical compositions, and using an incompatible gasket material can lead to degradation, leaks, or reduced performance.

2. Temperature Resistance:

Hydraulic systems can experience a range of temperatures. Select gasket materials that can withstand the temperature extremes encountered during operation. This ensures that the gaskets maintain their integrity and sealing properties under varying conditions.

3. Pressure Rating:

The hydraulic pump gaskets must be able to withstand the pressure generated within the system to prevent leaks and maintain efficient operation. Choose materials that offer the necessary strength and resilience for the specific pressure conditions.

4. Abrasion and Wear Resistance:

Due to often-used in rugged and abrasive environments, hydraulic pump gaskets should have good resistance to abrasion and wear to ensure durability and a prolonged lifespan. This is particularly important in agricultural settings where tractors may encounter debris, dirt, and other abrasive materials.

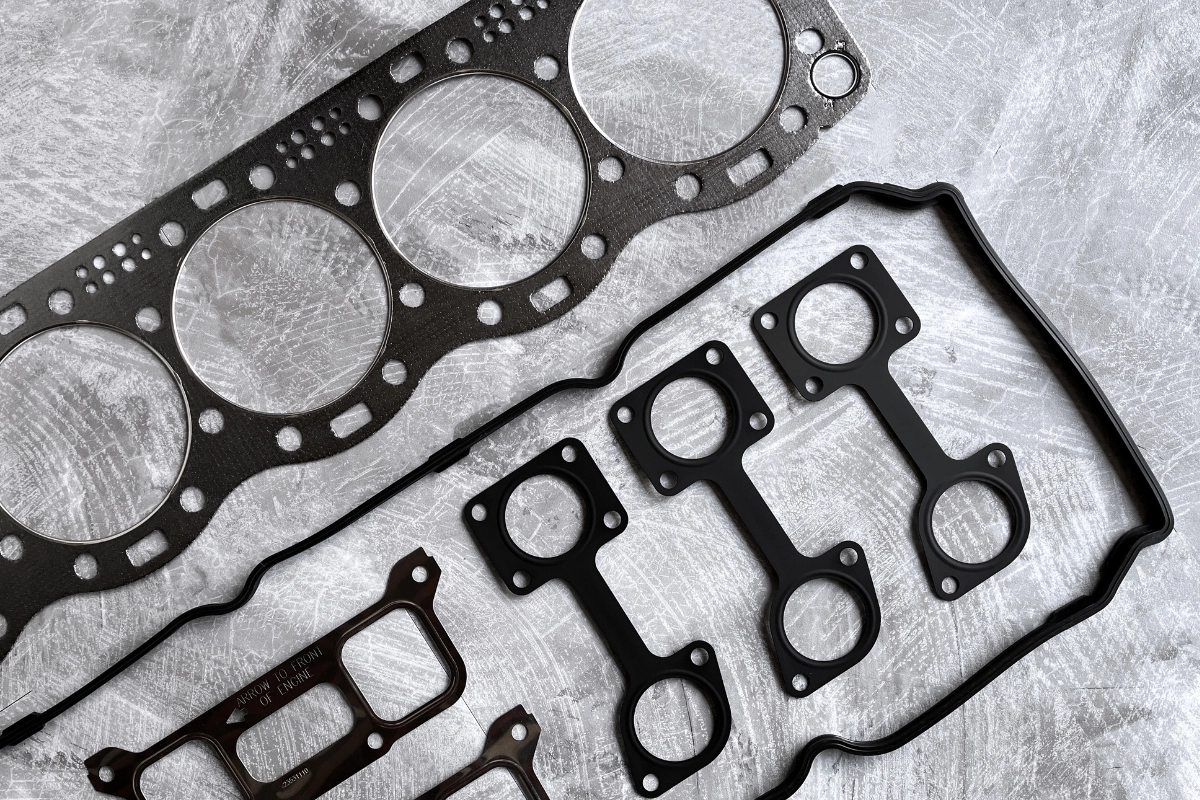

The 3 main materials used in hydraulic pump gaskets.

1. RCM(Rubber Coated Metal) gasket:

Offering excellent resistance to abrasion, lower maintenance costs, noise reduction, and easy fitting, these sheets are ideal for high-pressure applications such as hydraulic piston pumps. MJ Gasket sources its Rubber Coated Metal (RCM) raw materials from Wolverine Advanced Materials (WAM). Following a comprehensive comparison of RCM sheets from various companies, WAM stood out for its superior quality. The material’s edges demonstrate exceptional durability, remaining resistant to cracking even with high embossments.

2. Rubber Bonded Gaskets:

the purpose of rubber-bonded gaskets is to create a reliable seal while offering additional benefits such as vibration absorption (which is a very important material in hydraulic pumps); flexibility, and resistance to environmental factors. These characteristics make them valuable in a wide range of industrial applications.

3. Non-asbestos gaskets:

Non-asbestos hydraulic pump gaskets offer advantages such as improved safety and environmental impact, compliance with regulations, comparable performance to asbestos counterparts, and reduced maintenance needs. Their absence of asbestos enhances workplace safety and environmental friendliness, making them a reliable and efficient choice for hydraulic systems.

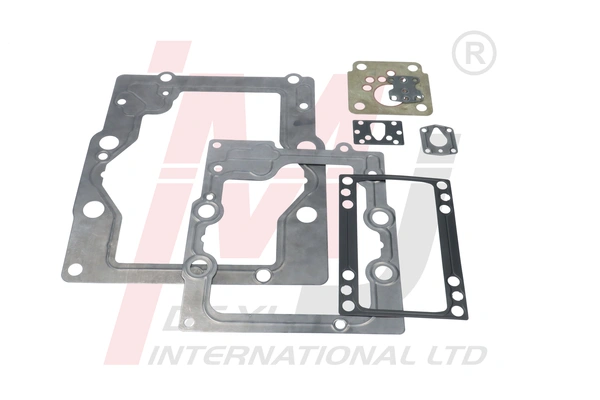

What type of hydraulic pumps gaskets does MJ Gasket offer?

At MJ Gasket, with over 40 years of expertise in heavy-duty engine gaskets, we specialize in high-quality hydraulic pump gaskets. Our commitment to the perfect fit is exemplified in our mission. Guided by the vision ‘Develop Nonstop,’ we stay curious, embracing new products and knowledge.

Explore our best-selling Hydraulic Pump Gaskets as below:

1. Rubber-Coated Metal Gaskets: This design ensures robustness and flexibility, leading to a reliable seal.

2. Metal Bonded with Rubber Gaskets: Our metal bonded with rubber gaskets, exemplified by the below products, combines metal durability with rubber’s sealing properties, providing resilience for demanding environments.

3. Non-Asbestos Gaskets: For those seeking asbestos-free alternatives, offering effective sealing without compromising safety.

When assembling a customized hydraulic pump repair kit for your customers, MJ’s high-quality gaskets are an ideal choice. We offer hydraulic piston pump gaskets compatible with most leading hydraulic brands, including Eaton, Vickers, and Danfoss. Our gaskets are made from top-grade materials such as metal bonded with rubber and RCM. Whether you need a large quantity or a smaller batch, we can accommodate your requirements. Simply provide us with the part number and quantity needed, and we’ll handle the rest.

If you require customized gaskets, you can also send us your product details or drawings for evaluation and a quote.

MJ Gasket’s dedication to excellence, backed by over four decades of experience, has resulted in high-quality gaskets that are now a promising product in the market. We’ve assisted numerous customers in expanding their businesses by providing top-notch gaskets. Our commitment to quality is underscored by the prestigious ISO 9001:2015 certification held for seven consecutive years, making us a certified gasket manufacturer recognized by GFA. Contact us for details.